Green(Un-fired) Ceramic Tape Processing Technology

HTCC

High-temperature co-fired ceramic materials mainly comprise alumina, mullite, and aluminum nitride. The ceramic powder of HTCC does not contain glass. The conductor paste is made of high melting point metal heating resistor paste such as tungsten, molybdenum, molybdenum, and manganese. Due to the high firing temperature, HTCC cannot use low-melting point metal materials such as gold, silver, and copper. It must use refractory metal materials such as tungsten, molybdenum, and manganese. These materials have low conductivity and will cause defects such as signal delay, so they are unsuitable—substrates for high-speed or high-frequency micro-assembled circuits. However, because HTCC substrates have high structural strength, high thermal conductivity, good chemical stability, and high wiring density, they have broad application prospects in high-power micro-assembled circuits.

LTCC

LTCC uses metals such as Au, Ag, and Cu with high conductivity and low melting points as conductor materials. Due to the low dielectric constant and low loss performance of glass ceramics at high frequencies, they are very suitable for use in radio frequency, microwave, and millimeter wave devices. They are mainly used in high-frequency wireless communications, aerospace, memory, drives, filters, sensors, automotive electronics, and other fields.

Modern LTCC technology is based on green porcelain tapes sintered at low temperatures. Capacitors, resistors, filters, and other components are embedded and laminated. They are then sintered at about 900-1000 degrees Celsius and finally made into high-density integrated circuits or built-in circuits. The 3D circuit substrate of passive components can also be mounted with active devices (transistors, IC circuit modules, etc.) on its surface to form an integrated functional module.

Green(Un-fired) Ceramic Tape Specifications

| Performance | HTCC Ceramics | LTCC Ceramics |

|---|---|---|

| Material | Aluminum oxide, aluminum nitride, mullite, etc. | Crystal phase ceramics, magnesium oxide, silica, alumina, etc. |

| Sintering temperature | 1500C-1800℃ | 850C-900℃ |

| Conductor material | Tungsten, molybdenum, manganese | Gold, silver, copper, platinum |

| Conductor Sheet Resistance | 8-12mΩ/cm | 3-20mΩ/cm |

| Dielectric constant | 8-10 | 5-8 |

| Resistance | N/A | 0.10Ω-1Ω |

| Sintering shrinkage (x,y) | (12-18)% | (12.0±0.1)% |

| Sintering shrinkage (z) | (12-18)% | (17.0±0.1)% |

| Line width | 100μm | 100μm |

| Through hole diameter | 125μm | 125μm |

| Number of metal layers | 8 or 63 | 33 |

| Thermal conductivity | 180-200W/m·K | 2-6W/m·K |

Green(Un-fired) Ceramic Tape Features & Production

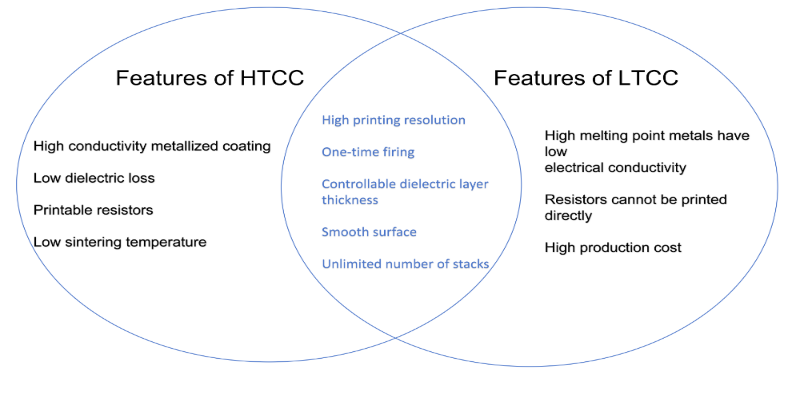

Features of LTCC and HTCC

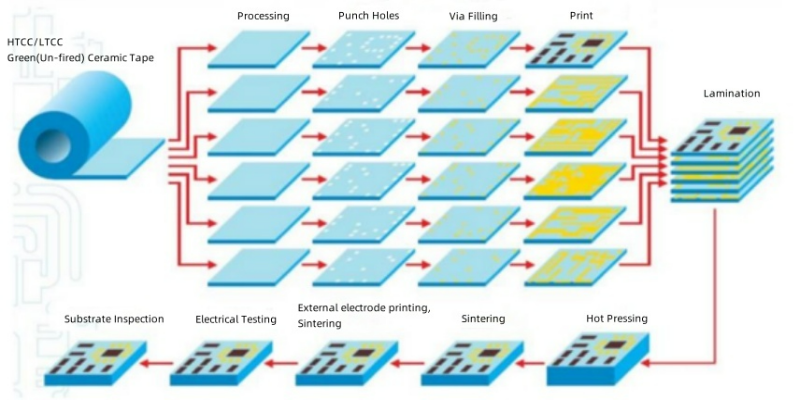

Production process of LTCC and HTCC

Workshop of Green(Un-fired) Ceramic Tape

Packaging

Our alumina plates are carefully handled to prevent damage during storage and transportation, ensuring the products remain in their original high-quality condition.

Green(Un-fired) Ceramic Tape FAQs

Green ceramic tape is commonly used in:

- Multilayer ceramic capacitors (MLCCs)

- Ceramic substrates for electronic circuits

- Multilayer ceramic packages

- Thick-film and thin-film circuits

- RF components and sensors

Green ceramic tape is typically produced by mixing ceramic powders with organic binders, plasticizers, and solvents. This mixture is then cast into thin sheets and dried, resulting in a flexible tape that can be cut, laminated, and shaped as needed before firing.

Advantages include:

- Flexibility and ease of handling before firing

- Ability to create complex multilayer structures

- High dielectric strength and excellent electrical properties after firing

- Good thermal conductivity

- Compatibility with various metallization processes

The processing steps typically include:

- Cutting and Shaping: Cutting the tape into the desired shapes and sizes.

- Lamination: Stacking and laminating multiple layers if a multilayer structure is needed.

- Metallization: Applying conductive patterns using screen printing or other techniques.

- Firing: Sintering the laminated and metallized tape in a kiln to achieve the final ceramic properties.

Yes, green ceramic tape can be customized in terms of thickness, composition, and size to meet specific application requirements. Customization allows for tailored electrical, mechanical, and thermal properties.

Green ceramic tape is available in various thicknesses, typically ranging from a few micrometers to several hundred micrometers. The specific thickness can be selected based on the requirements of the application.

Green ceramic tape should be stored in a cool, dry place to prevent moisture absorption and degradation of its properties. Handle it with care to avoid damage or contamination, and use gloves to prevent oils and dirt from affecting its surface.

Common materials include alumina (Al2O3), zirconia (ZrO2), and various other ceramic compositions depending on the desired properties such as dielectric constant, thermal expansion, and mechanical strength..

Ordering Information

Order alumina plates in the desired size and quantity. For bulk orders or custom requirements, please contact us for more details.

Reviews

There are no reviews yet.