Your Reliable Alumina Plate Manufacturer

Binzhou Aonuo New Material Technology Co., Ltd. Established its first company in Zibo on June 7, 2017, with a registered capital of 30 million.

The company is committed to developing the precision electronic ceramic substrate industry at home and abroad. It has new ceramic materials, powder preparation technology, a variety of advanced molding technologies, and high-temperature ceramic kiln sintering technology, which can meet the electronic functional parts and new functional materials required by various industries.

Our production applications and high-tech products have expanded into various industries, including mobile phones, electronics, electrical engineering, communications, machinery, environmental protection, new energy, and biology. This diversification underscores our adaptability and versatility.

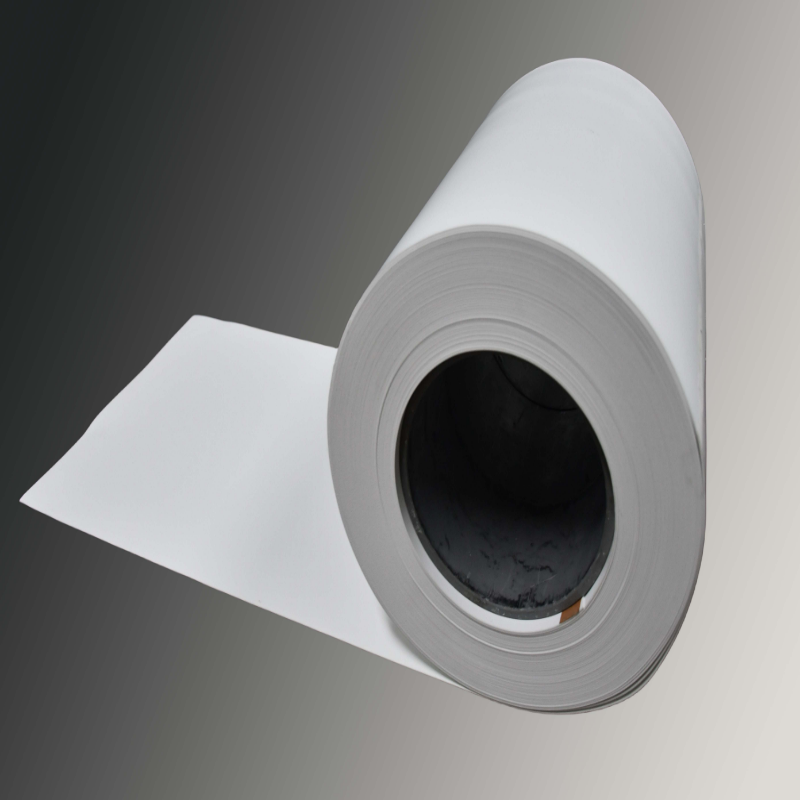

contact usTypes of Alumina Plate We Made

Get Your Alumina Plate Customized

Aonuo is a trusted alumina substrate manufacturer with years of experience creating high-quality solutions for various industries. It specializes in manufacturing high-quality custom alumina plates to meet customers’ different needs. Here are your custom selections:

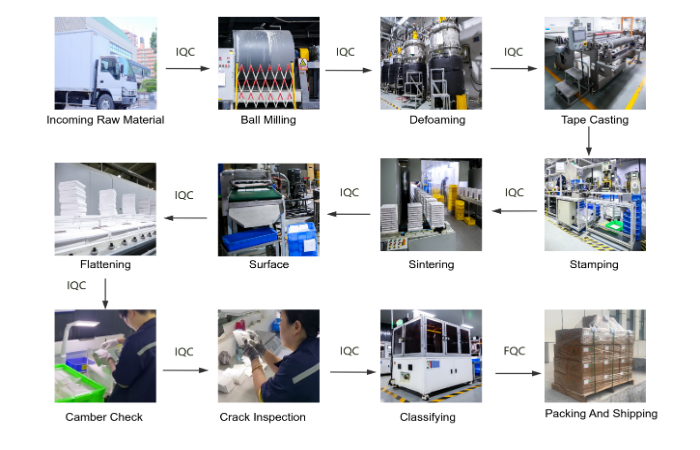

Alumina Substrate Manufacturing Process

The production process of alumina ceramic plates involves several key steps:

Powder Processing: Alumina powder is mixed with binders, plasticizers, and solvents to form a homogenous slurry.

Ball Milling: The mixture is ground into a fine powder to achieve the desired particle size distribution.

Tape Casting: After drying, the alumina slurry is cast into thin layers on a flat surface, forming green ceramic sheets.

Pressing: The alumina powder is pressed into molds to create green bodies with the desired shape.

Air Drying: Green bodies are exposed to air at room temperature to remove solvents.

Controlled Drying: Performed in controlled environments to prevent cracking and ensure uniform drying.

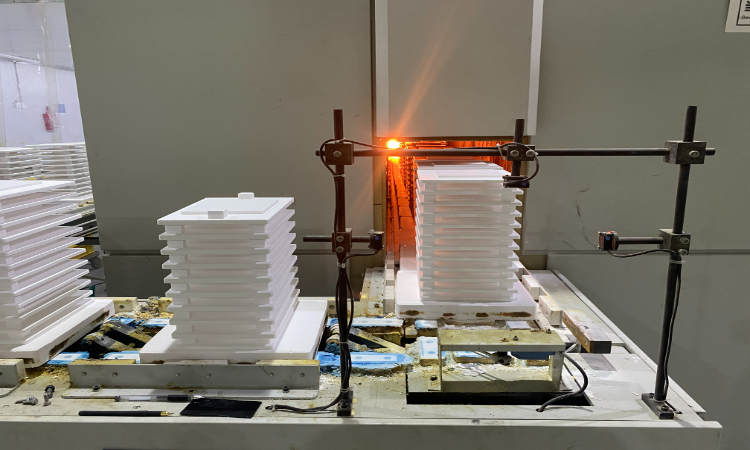

Pre-Sintering: Green bodies are heated to burn off organic binders.

Main Sintering: Heating to high temperatures (typically 1500°C to 1800°C) to densify and strengthen the material.

Machining: Grinding and polishing to achieve the required thickness and surface finish.

Metallization: Applying metal layers for electrical connections using methods like screen printing or vapor deposition.

Inspection and Testing: Checking for defects and testing for electrical and thermal performance.

This process results in high-quality alumina ceramic plates used in electronic applications for their excellent thermal and electrical properties.

GET A FREE QUOTE

Alumina Plate Research And Development

Research and development in industrial alumina ceramic plates aim to push the boundaries of their capabilities, making them more versatile, durable, and suitable for a broader range of applications. This ongoing R&D effort is crucial for maintaining a competitive edge in various high-tech and industrial sectors.

Research and development (R&D) in industrial alumina ceramic plates focus on enhancing their properties, improving manufacturing processes, and expanding their applications. Below are the main areas of R&D in this field:

- Purity Improvement: Developing methods to increase the purity of alumina to enhance mechanical strength, thermal stability, and electrical insulation properties.

- Doping and Additives: Introducing dopants (such as magnesium oxide) to improve properties like toughness, thermal conductivity, and resistance to thermal shock.

- Composite Materials: Creating alumina-based composites by combining alumina with other materials like zirconia to improve mechanical properties and wear resistance.

- Advanced Sintering Techniques: Exploring new sintering methods such as hot isostatic pressing (HIP), spark plasma sintering (SPS), and microwave sintering to achieve better densification, reduced grain growth, and enhanced properties.

- 3D Printing and Additive Manufacturing: Utilizing additive manufacturing techniques to produce complex geometries with high precision and minimal material waste.

- Green Manufacturing: Developing environmentally friendly production processes, including recycling waste materials and reducing energy consumption during manufacturing.

- Advanced Coatings: Applying wear-resistant, thermal barrier, or anti-corrosion coatings to extend the lifespan and functionality of alumina plates.

- Surface Modification: Techniques such as laser texturing, chemical etching, or plasma treatments to improve surface properties for specific applications.

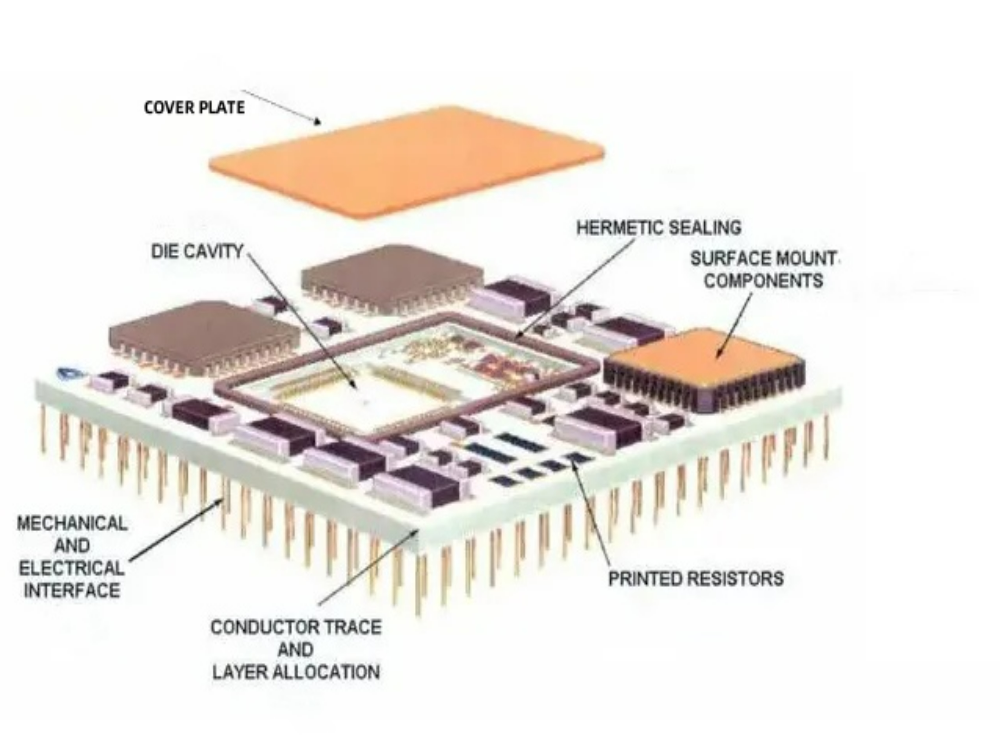

- Multi-Layered Structures: Researching the integration of alumina plates with other materials to form multi-layered structures for enhanced performance in electronic or thermal management applications.

- Bonding Techniques: Developing advanced bonding techniques to integrate alumina plates with metals, polymers, or other ceramics for hybrid components.

- Electronics: Enhancing the electrical insulation properties of alumina plates for use in high-voltage applications and as substrates for electronic circuits.

- Thermal Management: Improving alumina plates’ thermal conductivity and thermal shock resistance for applications in heat exchangers and high-temperature environments.

- Wear and Corrosion Resistance: Developing alumina plates with superior wear and corrosion resistance for use in harsh industrial environments, such as in machinery and chemical processing.

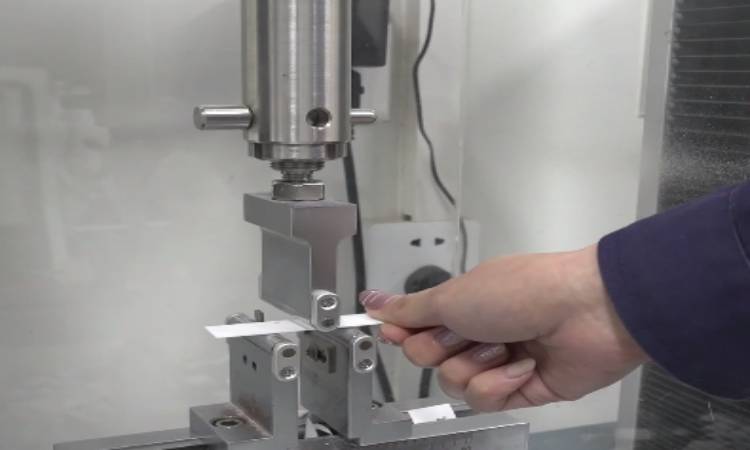

- Non-Destructive Testing (NDT): Implementing advanced NDT methods to detect defects and ensure the quality of alumina plates without damaging them.

- Failure Analysis: We proactively study the failure modes of alumina plates under various conditions to understand the causes and develop effective strategies to mitigate them, instilling confidence in our problem-solving approach.

- Standards and Certification: Meeting and exceeding industry standards to ensure reliability and performance consistency.

- Medical Applications: Exploring the use of biocompatible alumina plates in medical devices and implants.

- Renewable Energy: Developing alumina plates for use in renewable energy technologies, such as components in solar panels and wind turbines.

- Aerospace and Defense: Enhancing properties to meet the stringent requirements of aerospace and defense applications, such as high-temperature resistance and lightweight characteristics.

- Industry-Academia Partnerships: Collaborating with universities and research institutions to leverage cutting-edge research and translate it into industrial applications.

- Innovation Hubs: Participating in innovation hubs and consortiums to stay at the forefront of technological advancements and industry trends.

Advantages Of Alumina Ceramic Plates

Superior Thermal Management:

Ceramic substrates offer exceptional thermal conductivity, ranging from 28-35 W/m-K for alumina to 170-280 W/m-K for beryllium oxide. This superior heat dissipation capability prevents hot spots and allows higher power density designs, which is crucial for high-performance electronic applications.

Excellent Electrical Insulation:

These substrates provide reliable electrical insulation, preventing current leakage and ensuring the integrity of electrical circuits. This property is essential for maintaining device performance and safety in high-power applications.

Alumina Plates Application

A ceramic plate is a material used in electronic circuits known for its excellent thermal and electrical properties. In this article, we will explore some of the many applications of ceramic substrates.

Power Electronics

Ceramic substrates are essential in power modules for electric vehicles, inverters, and industrial motor drives. Their high thermal conductivity efficiently dissipates heat from high-power semiconductors, while their excellent electrical insulation properties ensure reliable performance in demanding environments. This combination enables more compact and efficient power electronic designs.

LED Lighting

Our ceramic substrates serve as the foundation for high-performance LED packages. Their superior thermal management capabilities allow LEDs to operate at higher brightness levels without overheating, extending lifespan and improving efficiency. The substrates’ customizable surface properties also enhance light extraction and overall luminaire performance.

RF and Microwave Devices

Ceramic substrates are crucial for high-frequency applications in telecommunications and radar systems. Their low dielectric loss and excellent dimensional stability enable precise signal transmission and reception. Our substrates support the development of compact, high-performance antennas and filters for 5G networks and satellite communications.

Automotive Electronics

Ceramic substrates are integral to various automotive electronic components, including engine control modules and advanced driver assistance systems (ADAS). Their ability to withstand high temperatures and harsh environments makes them ideal for under-hood applications, ensuring reliable operation of critical vehicle systems.

Why Choose Us as Alumina Plate Supplier

Unrivaled Manufacturing Expertise

With over two decades of experience in ceramic substrate production, our team has honed its skills perfectly. We’ve successfully delivered millions of high-quality substrates across diverse industries, from automotive electronics to aerospace applications. Our deep understanding of material properties and manufacturing processes ensures consistent, top-tier products that meet the most demanding specifications.

Cutting-edge Technology and Innovation

We invest heavily in state-of-the-art equipment and continuous R&D, keeping us at the forefront of ceramic substrate technology. Our advanced clean room facilities and proprietary manufacturing techniques allow us to produce substrates with industry-leading thermal conductivity and electrical insulation properties. We’re not just meeting current industry standards – we’re setting new benchmarks for performance and reliability.

Competitive Factory-Direct Pricing

By maintaining a vertically integrated production model, we eliminate intermediaries and pass the savings directly to you. Our efficient manufacturing processes and economies of scale enable us to offer factory-direct pricing without compromising quality. We provide transparent quotations and flexible pricing options to accommodate large-volume orders and specialized small-batch requirements.

Rigorous Quality Control and Timely Delivery

Our ISO 9001:2015 certified quality management system ensures stringent quality control at every production stage. We stand out by employing cutting-edge testing equipment and methodologies, including X-ray inspection and thermal imaging, to guarantee that every substrate meets or exceeds industry standards. Furthermore, our strategic global logistics partnerships ensure timely and secure deliveries, with real-time tracking available for all shipments

Our Partner

Alumina Plate FAQs

Alumina substrates offer superior thermal conductivity, excellent electrical insulation, high mechanical strength, and low thermal expansion. These properties make them ideal for high-power and high-frequency applications, ensuring reliable performance and longevity in demanding environments.

Common materials for ceramic substrates include alumina (Al2O3), aluminum nitride (AlN), silicon carbide (SiC), and beryllium oxide (BeO). Each material is selected based on specific application requirements such as thermal conductivity, electrical insulation, and mechanical strength.

We implement rigorous quality control measures throughout the manufacturing process. This includes inspecting raw materials, monitoring forming and firing processes, conducting dimensional and electrical tests, and performing visual inspections to ensure our substrates meet the highest standards.

We offer extensive customization options, including different sizes, shapes, thicknesses, and surface finishes. We also provide various metallization options and can integrate specific design features to meet your unique application requirements.

The lead time for ceramic substrate orders varies depending on the complexity and volume of the order. Generally, standard orders are fulfilled within 4-6 weeks. For customized or large-volume orders, we provide a detailed timeline upon order confirmation to ensure timely delivery.

We have established partnerships with reliable global logistics providers to ensure the secure and timely delivery of our products. We offer various shipping options, including air and sea freight, and provide real-time shipment tracking. Our team handles all necessary documentation and customs clearance to facilitate smooth international transactions.